Automated Continuous Ambulatory Peritoneal Dialysis Device

Introduction

Renal Replacement Therapy (RRT) includes various methods to replace healthy kidneys' essential waste filtration function. Kidney failure disrupts the body's balance of electrolytes, fluids, and acid-base levels, necessitating RRT to manage resulting metabolic imbalances. For those with End Stage Kidney Disease (ESKD), RRT becomes a necessity, as kidney transplantation is limited by donor availability and potential transplant failures. Many ESKD patients rely on dialysis, which removes excess water, solutes, and toxins from the blood. The primary dialysis types are hemodialysis, an "artificial kidney" dialyser, and peritoneal dialysis, which filters blood within the abdominal cavity to correct electrolyte imbalances by removing waste products and fluids.

Peritoneal dialysis is a well-established treatment for people with end-stage renal disease (ESRD). It relies on the peritoneal membrane, a thin tissue layer that lines the abdominal cavity, to naturally filter out waste products and excess fluids from the body. To do this, a catheter is inserted into the peritoneal cavity, providing access to the dialysis solution, known as dialysate. The dialysate is introduced into the peritoneal cavity and remains there for a specific period, allowing the exchange of waste products and toxins through the peritoneal membrane.

There are two main types of peritoneal dialysis: Continuous Ambulatory Peritoneal Dialysis (CAPD) and Automated Peritoneal Dialysis (APD). CAPD involves manual dialysis exchanges throughout the day, whilst APD, on the other hand, uses a cycler machine to automate the exchanges, typically done overnight while the patient sleeps.

Problem Statement

Hemodialysis is the primary dialysis method widely used in our region, especially in Ghana. However, the shortage of hemodialysis centres has led some healthcare facilities to consider a CAPD as an alternative due to its cost-effectiveness. CAPD is commonly employed, particularly for children with acute kidney injuries, as a renal replacement therapy.

However, it's essential to recognise that CAPD has its limitations. It is a labour-intensive process, mainly because it involves manual steps. Healthcare providers must wait several hours as a medical attendant's presence is required throughout the CAPD procedure.

In light of these challenges, the problem statement focuses on the labour-intensive nature of Continuous Ambulatory Peritoneal Dialysis, primarily resulting from the manual aspects of the process.

Purpose of Study

The main goal of this project is to design and build a low-cost device with a robust interface that controls the entire continuous ambulatory peritoneal dialysis setup with minimal or no human intervention.

Objectives of Study

- Combine mechanics, electronics, and programming to automate continuous ambulatory dialysis setup.

- Incorporate all of the details of the manual process into our design.

- Incorporate sensors and alarm systems into the device.

- Provide means of monitoring the process.

Methodology

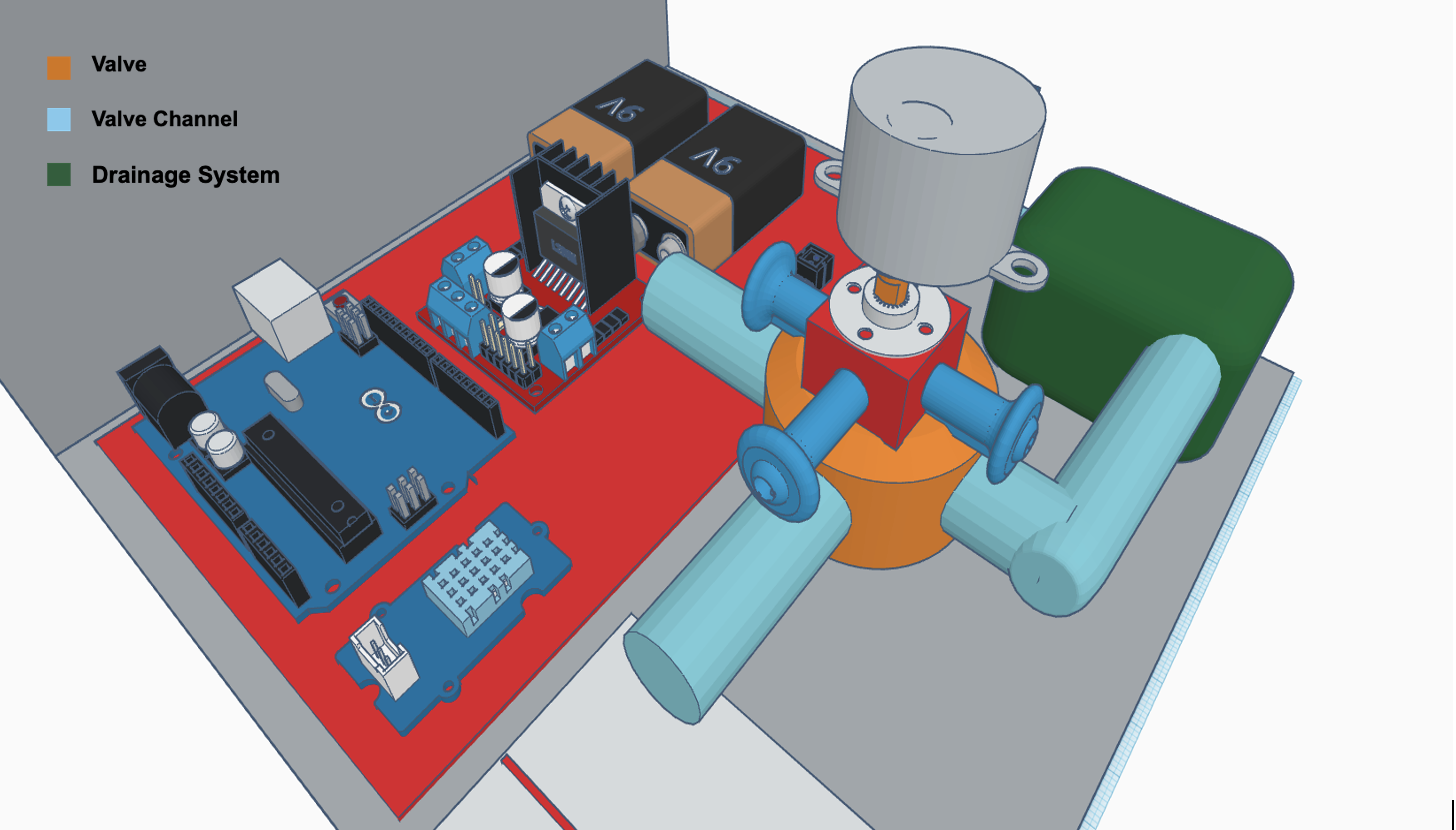

Our proposed design comprises three key components: the valve control system, the drainage control system, and the monitoring system. In the continuous ambulatory peritoneal dialysis procedure, various phases, including rinse, inflow, dwell time, and drain, require manual valve switching, with gravity facilitating the dialysate's movement. Our design incorporates a microcontroller, a unipolar stepper motor, and a timer for the valve control system to automate these phases.

The drainage control system operates by creating negative pressure to draw out liquid. This system includes a pressure pump, which maintains an average pressure of ±10.3 kPa or 77.6 mmHg, a flow sensor, and a timer to monitor the drainage process and collect the drained liquid.

The monitoring system involves an alarm system and a GSM module for notifying caregivers or nurses about the procedure's progress. An LED indicates the system's operational status and an LCD indicates the procedure's current status. By integrating these three components, our design results in a cost-effective, intelligent dialysis device suitable for home and hospital use.